by Bill Lavender, circa 1998

FRANKLIN, NC – The gypsy moth control program by the USDA has been around for quite a while. Traditionally, the program has been in the northeastern part of the United States. Until recently, the gypsy moth infestations have been reasonably regional. But with the advent of mobile campers, hikers and such, the eggs of the gypsy moth have found their way south into the North Carolina Smoky Mountains. Today, the gypsy moth larvae are fought with aerial application through a cooperative of private applicators on bid, the State of North Carolina Department of Agriculture and USDA.

Maurice Quesnel (pronounced “Ca-nel”) owns and operates Maurice’s Flying Service in Lakeview, Michigan. During late spring, he exercises contracts for gypsy moth larvae control with two of his three Ayres Turbo Thrushes. All three of Maurice’s Thrushes are S2R-G10/510. This translates into three Garrett-powered 940 hp machines, all with 510-gallon hoppers.

One of the -10s is an Ag Air Systems Inc. conversion. Maurice bought this aircraft with a -5, but quickly exchanged the engine for a -10. The second -10 aircraft is a new 1997 Ayres factory model beginning its first full season this year. The third -10 is an Ayres factory version, serial #2.

Gypsy moth spraying is a bit different from routine row crop applications, as is all forestry work. The pilot is often trying to identify area boundaries with little or no reference points. As in the case of the Franklin contract, the applications are made in the mountains where many of the turns are at 4,500 MSL or more and spray runs often lead into canyon-like boxed-in valleys. Much caution and pre-planning are needed. Maurice’s Flying Service is well equipped to do the job.

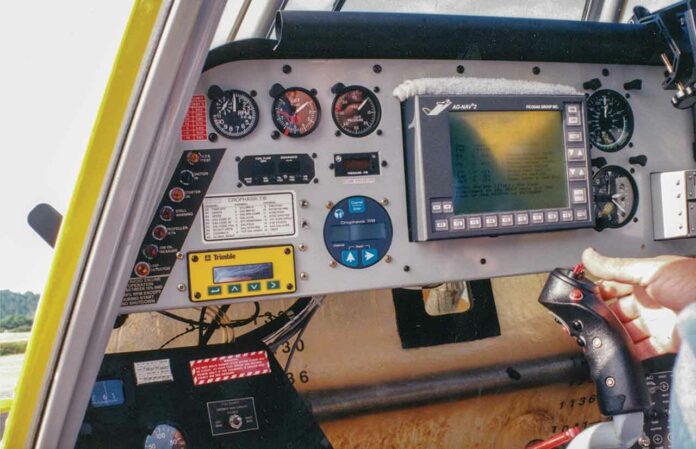

The moving map GPS is a must. Maurice has found that the AG-NAV GPS units work best for his operation. Maurice’s Flying Service’s aircraft may very well be some of the most sophisticated ag aircraft in the field today. Each are outfitted with a top-of-the-line AG-NAV GPS unit, transponder, com radio, nav GPS, Crophawk 7/B interfaced with the AG-NAV unit, Crophawk fill meter, air conditioning and a GPS antenna capable of receiving Coast Guard, L-band and satellite signals. The L-band signal is furnished by Ominstar. The antenna is mounted on a Star-Flex GPS mount.

With the moving map feature of the AG-NAV, Maurice’s Flying Service’s pilots can monitor their applications in real time. The route of the plane’s application is plotted in the cockpit during the application allowing the pilot to make corrections wherever necessary. All of the information is stored on a 3 1/2 inch floppy disk. The disk is reviewed for accuracy and serves as proof of application.

The North Carolina project is managed by Mike Massey, along with a host of assistants. They scout the 6,500-acre rectangular block for egg masses. Traps are placed every four square miles. These egg masses are monitored for the hatch-off of the larvae. When the larvae are in the first to second instar stages of development, Massey initiates the spraying. There is a ten-day window for treatment.

Bacillus thuringiensis, subspecies kurstaki (Bt, trade name Foray 48-B) is the product of choice. The material is applied at 64 ounces per acre in the concentrate form. A second application is made after completion of the first to catch any delayed hatchings.

Approximately 200 acres were set aside for a GypChek application. This is a test application of what amounts to dried up gypsy moth bodies that are suppose to transmit, or rather infect, a lethal virus into the target larvae. The gypsy moth polyhedral inclusion bodies are mixed with molasses and applied over the target area. The larvae are attracted to the molasses, ingesting the 28.6 billion viral bodies per gram. Seven hundred grams are mixed in 100 gallons of water applied at one gallon per acre.

Applications are conducted at 50-100 feet above the forest canopy depending on the terrain. Swath width is set at 100 feet. The aircraft are outfitted with 8008 flat fan nozzles angled at 90° down operated at 40 psi. Applications are restricted to less than 40% relative humidity, less than 80°F and wind speed less than 10 mph.

Maurice discovered flying in the Great Smoky Mountains to be a challenge, even with the powerful -10 Thrushes. Loads were limited to a maximum of 250 gallons. Power settings were at 525-535°C on the EGT gauge, developing about 800 SHP and the engine burning 58-63 gallons of fuel per hour. Maurice stated that the fuel flow was the best indicator he had found for the amount of power to use. Thus, easing the coordination of formation flying.

Upon arrival at the North Carolina project, Maurice plugged in the coordinates provided by the North Carolina Department of Ag for the application block. Within the block were two “no-spray” zones of 1000 acres. With the moving map features of the AG-NAV units it was a simple matter to identify the boundaries of the spray block and the no-spray areas.

Maurice, with second Ayres Thrush and pilot, Bruce Andrews, in formation, attempted to fly the block on the longer north-south line. However, due to the mountainous terrain the block had to be flown east and west with some portions following the terrain.

“Bill”, Maurice confided, “I won’t be bidding any more forestry contracts without first flying over the spray block. This has to be some of the most difficult flying I’ve ever encountered. We are often climbing out

over ridges as high as 4,300 MSL requiring loaded turns at even higher altitudes, the reason for the small 250-gallon loads.”

Maurice’s Flying Service finished the North Carolina gypsy moth contract on schedule within the prescribed 10-day window. Maurice and Bruce flew the -10 Thrushes back to Michigan to prepare for the potato spraying season. Bruce caught the next airline from Michigan to Georgia to return to his flying service in Arlington, Georgia to spray cotton and peanuts.

There will be more gypsy moth contracts for aerial applicators. It’s not the kind of spraying that can be accomplished by a typical ag operation. There are many important considerations. However, forestry aerial applications are becoming more important to the ag aviation industry with each passing year. It is flying services like Maurice’s Flying Service, whose expertise will continue to build the confidence of the various government agencies and private companies that are involved in forestry protection with agricultural aircraft.